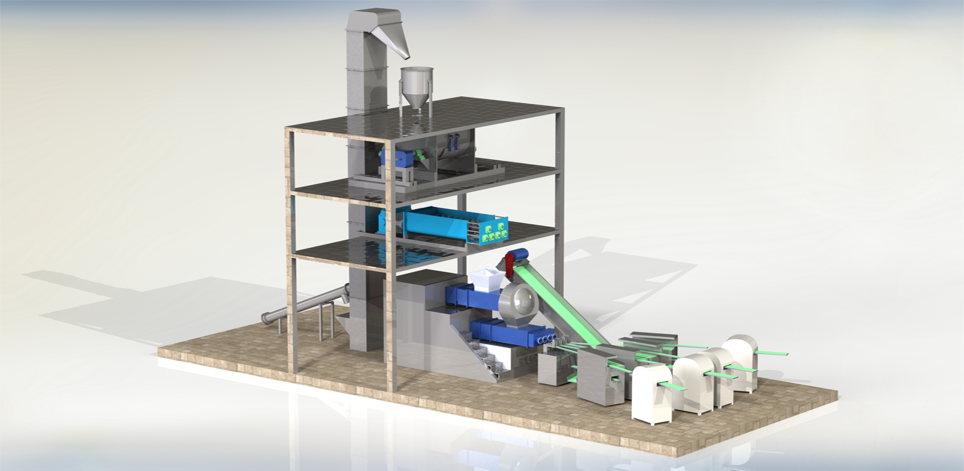

Detergent Cake Plant

Detergent Cake is detergent in cake form, which can be used with hand as well as in soft water. Detergent cakes are generally formulated using one or more surfactants to improve their cleaning performance and make them good even for use in hard water conditions.

The operation depends on client’s customize requirement i.e. Manual handling, Semi-automatic and fully automatic.

The basic process comprises of all the raw materials being added into a mixer as per the sequence of additions and mixed till the reaction is completed. The mass is then dropped and fed through multiscrew to extrusion plodder to take shape into Bar as per the extrusion mouth piece is set at the final plodder discharge.

The extruded bar is conveyed to a tablet cutter cum stamper automatic machine to desire size cuts from where it is further take away to flow wrapping machine directly.

We provide the plant capacity ranging from 200 Kg./ Hr. to 4000 Kg. per hour.

The main process equipments used are:

Sigma Mixer

Sigma Mixer

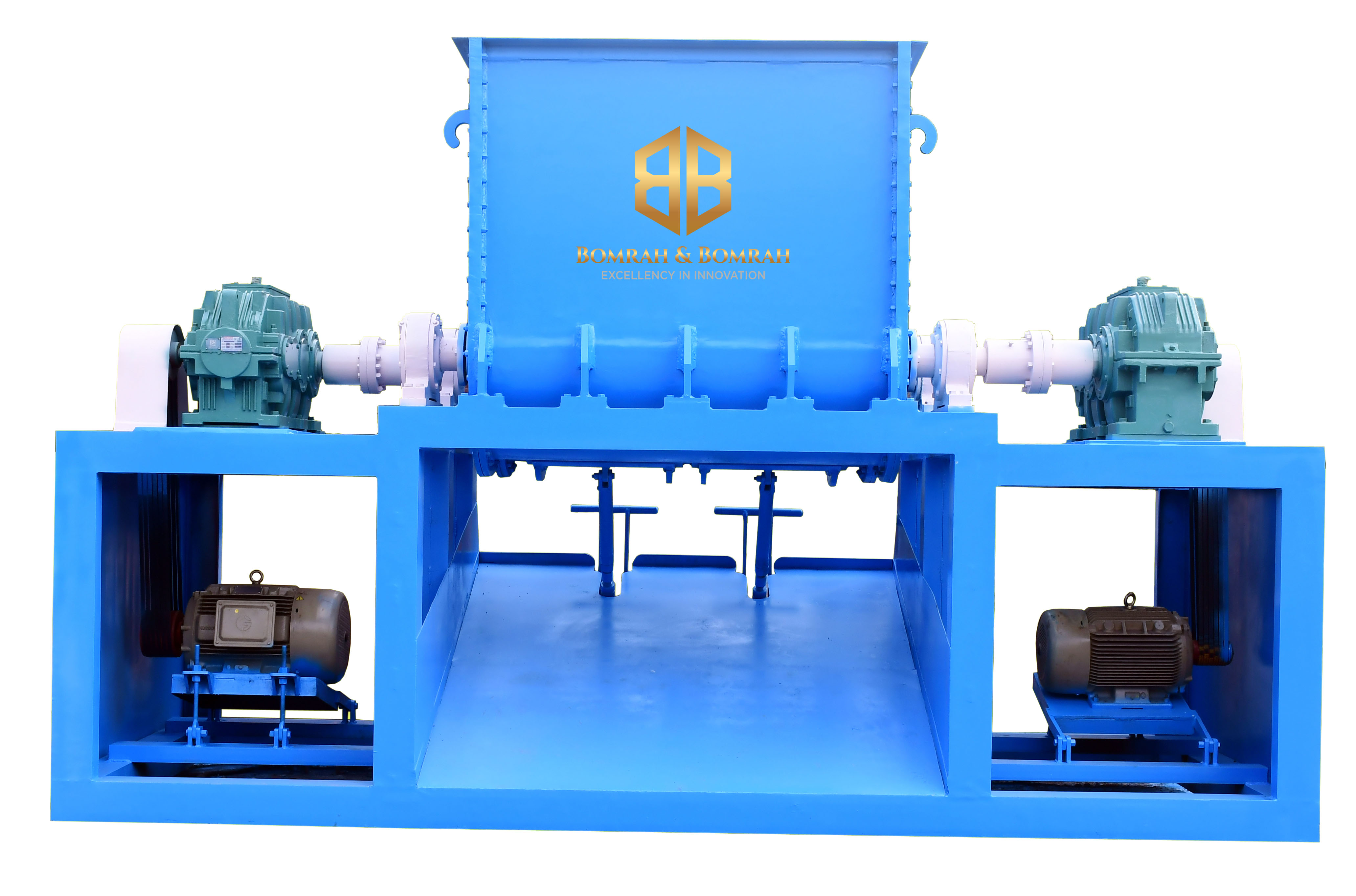

Multy Screw Feeder

Multy Screw Feeder

Multi Screw Feeder is used to transfer the material from Sigma Mixer Discharge to Plodder.There are six specially designed screws used for transferring as well as crushing the dough shaped material into small pieces which is gradually feed to plodder as per its requirement.The material of construction is available as per the requirement in M.S and S.S.

Plodder

Plodder

Rottery Bar cutter

Pneumatic Bar cutter

Cutting Machine

Cutting Machine