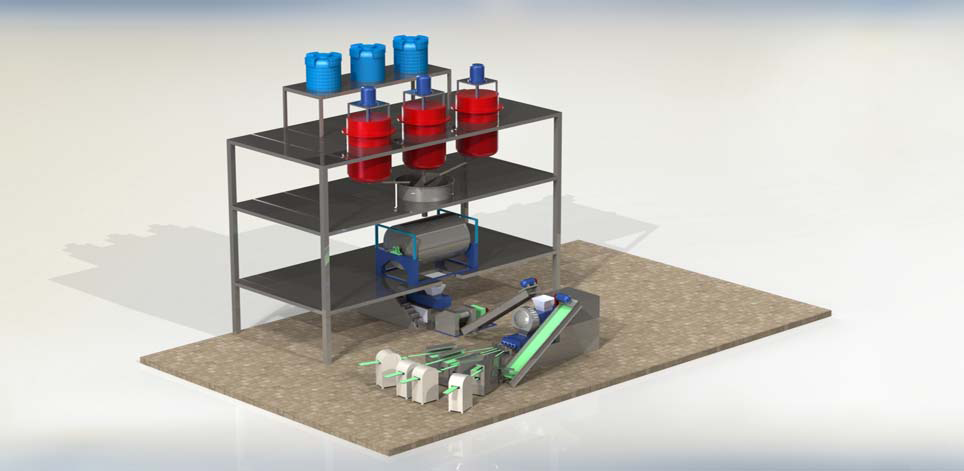

Toilet / Laundry Soap Plant

The semi-boiled process differs from the cold process in the fact that the saponification Crutcher is heated to 70 - 90° C using a steam-heated jacket to accelerate and complete the saponification reaction. Dyes, perfumes, and additives are added at the end of the process to prevent them from evaporating.

The process allows the quantity of caustic soda lye undergoing saponification to be adjusted before the crude soap is drawn off. It also allows manufacturing waste to be recycled, better incorporation of the additives and a wider choice of raw materials. Generally speaking, saponification is more complete and the hardening time of crude soap is carried out through Chilled Roll flakers. The crude soap from Crutcher discharge is poured at center of moving rolls which due to chilled water flowing inside the Rolls loss temperature and dried immediately to desired hardness. These flakes are passed through Duplex Vacuum Plodder where at the final plodder discharge Bar comes out to desired shape which can be cutted and embossed as per requirement and size.

The main process equipments used are:Soap Crutcher

Soap Crutcher

Sigma Mixer

Sigma Mixer

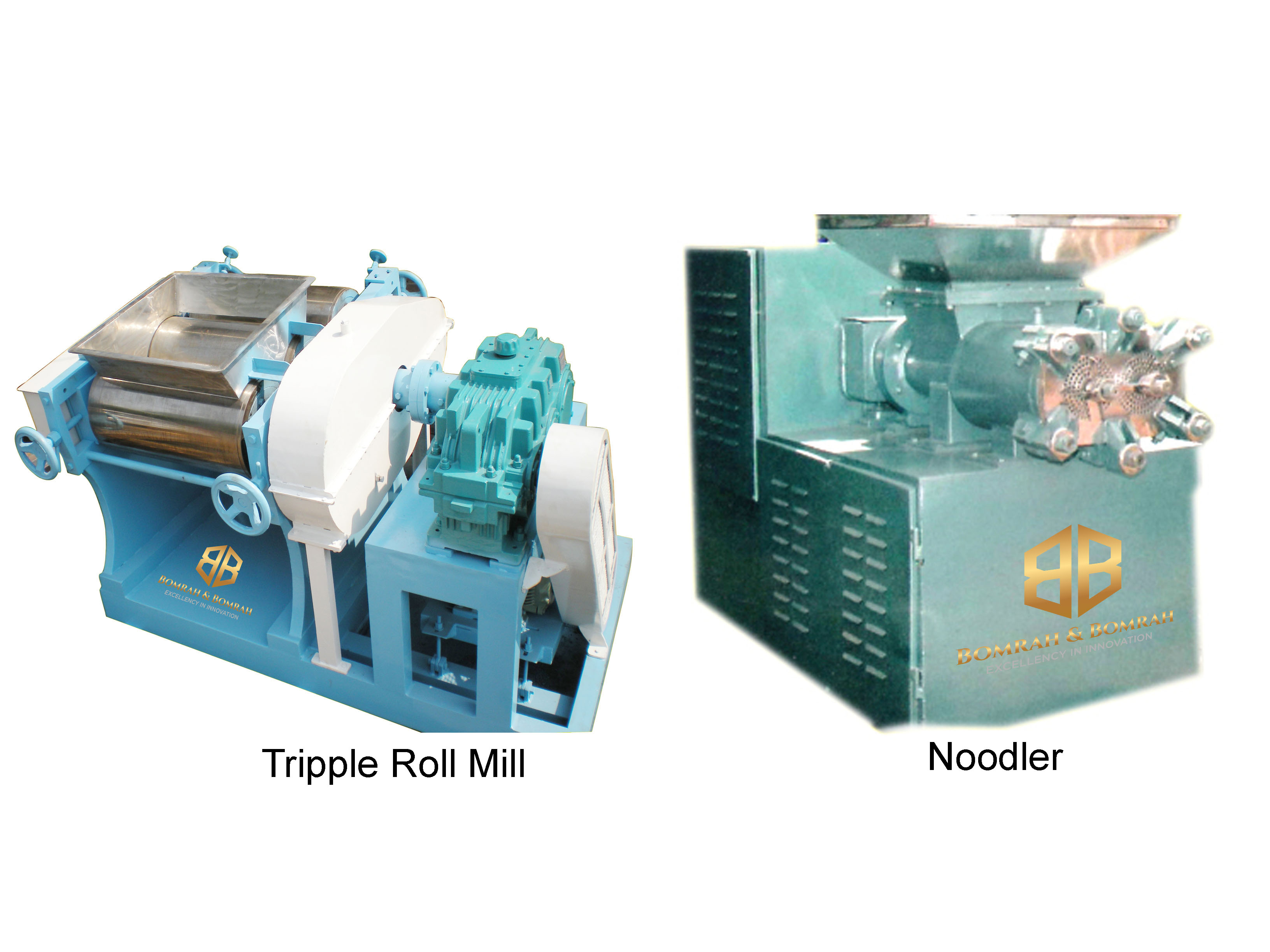

Tripple Roll Mill / Noodler

Tripple Roll Mill / Noodler

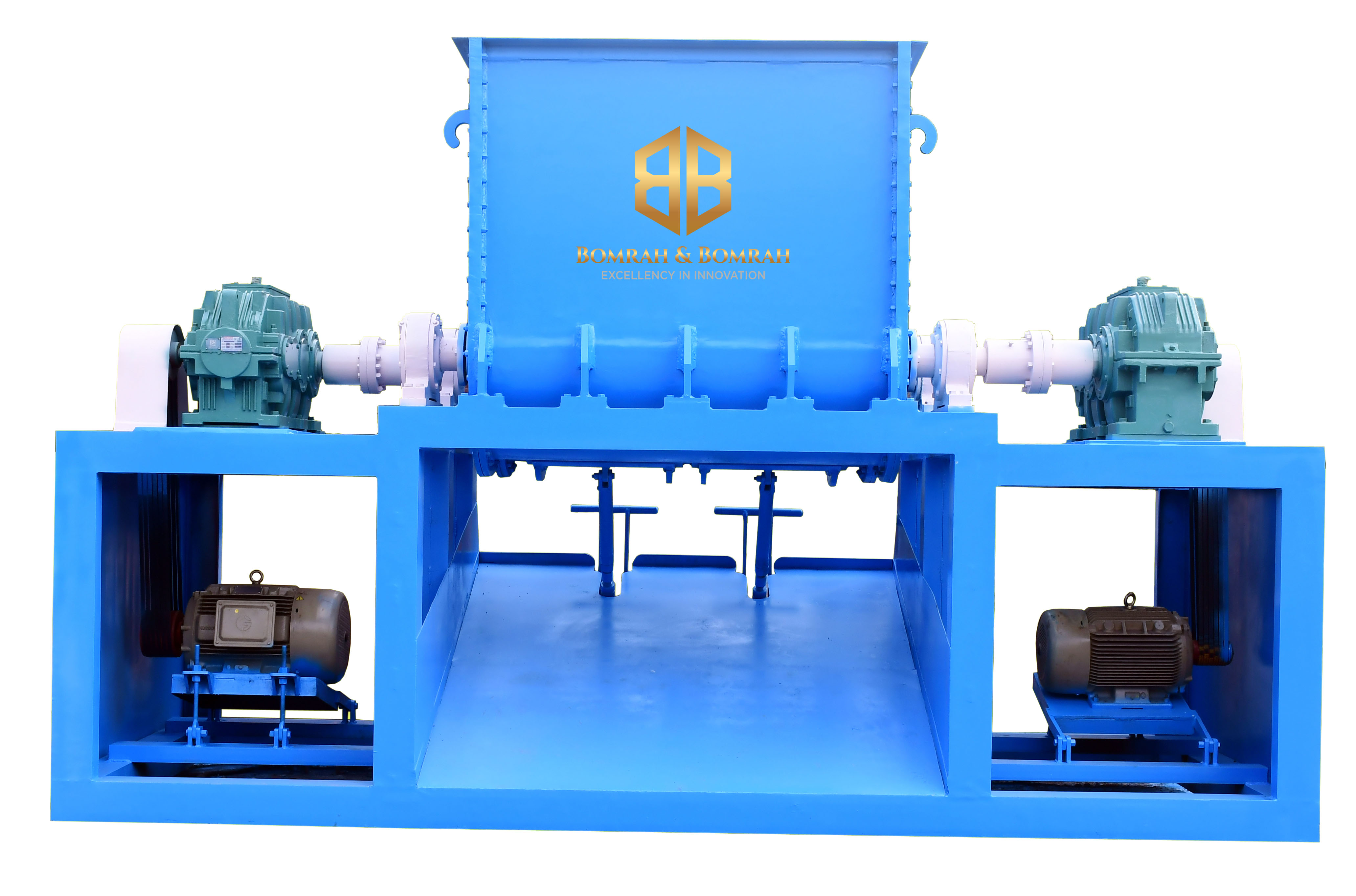

Twin Worm Duplex Vaccum Plodder

Twin Worm Duplex Vaccum Plodder